About Us

Possessed technology

- RND part

- Production part

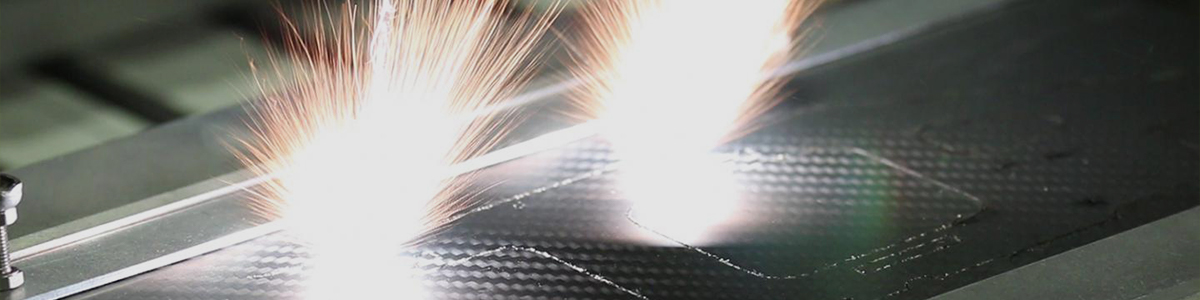

Frei Scan System

Micro processing can be expanded to a large area. Large film processing, large-area patterning, and FPCB processing are possible.

Laser Marking

Because it uses the galvo meter method, it has excellent dynamics and precision compared to the general servo motor method.

Micro drilling

Micro imprint

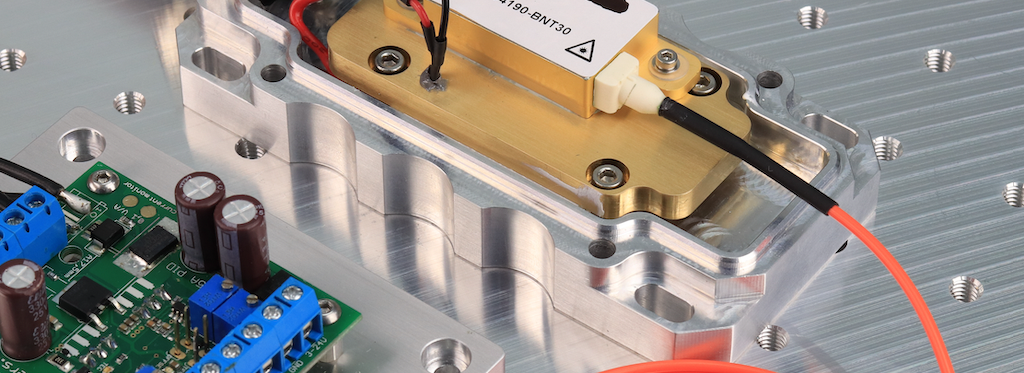

- Laser control electronics (Cutting, Marking, Cleaning)

- Laser control program (RTC series, Marking Mate series application)

- Automation facility control program (PLC, PC, Opcua application)

- ARM Applied Electronic Circuits and Programs

- Radio control circuit

- Inverter circuit

- Multi-axis universal motion controller and program

- Smart factory construction project (cloud server linkage)

- Makerspace operation support

- Development of plastic injection parts (mold development)

- Development of die casting injection parts

- Development of vacuum molded products and production facilities

- Automatic MCT processing and processing machine development (including automation)

- Development of pressed products

- Blower mold product development

- Automated production based on laser cutting, marking, cleaning, and welding

- Laser equipment utilization technology training support