LASER SYSTEMS

CO2 laser processing machine

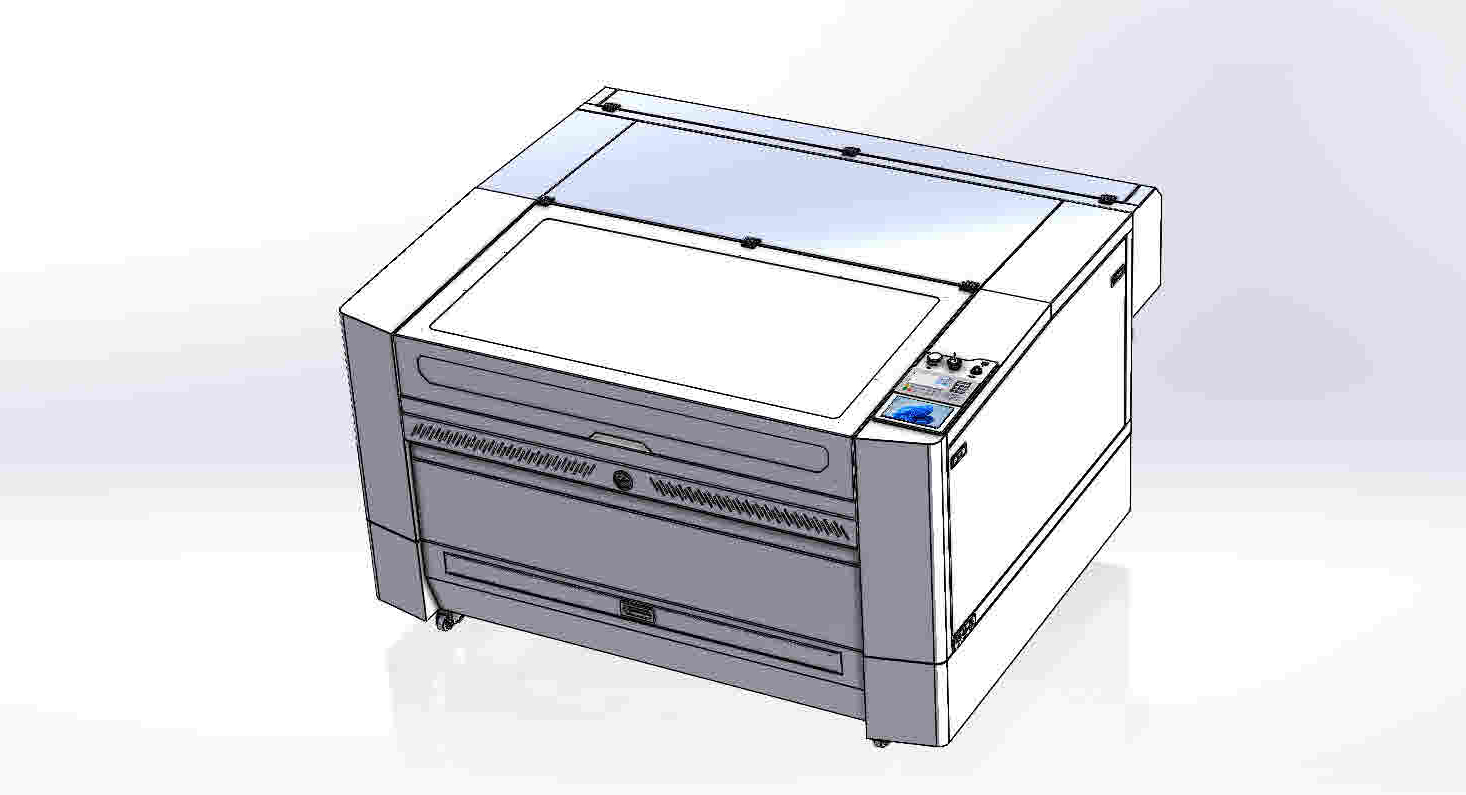

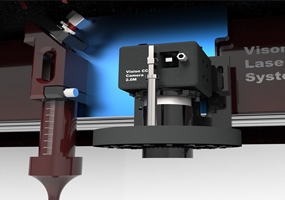

TALENTO 9 Hybrid

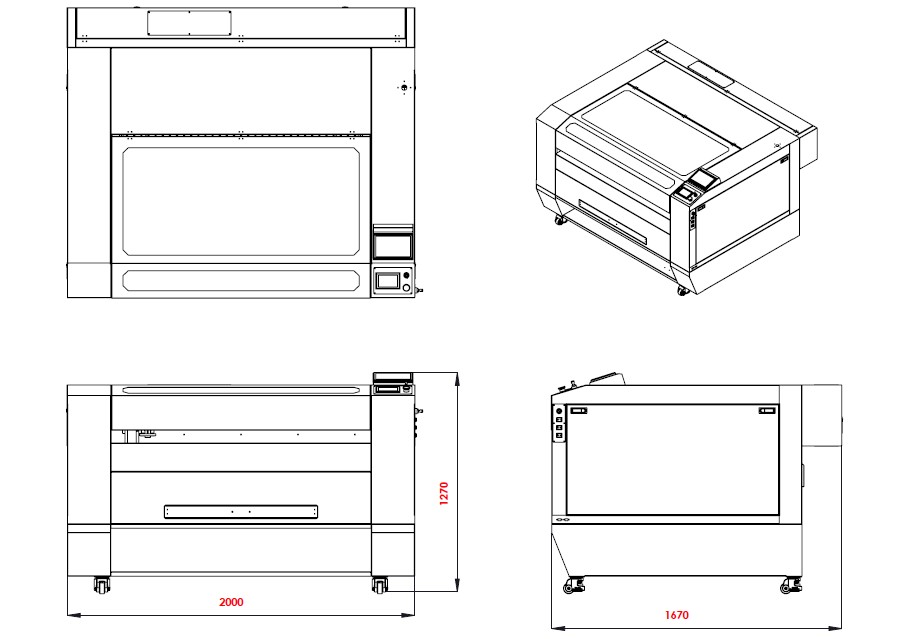

| Basic Specifications | Options | |

|---|---|---|

| Work area | 1300*900mm | |

| Laser | DC 300W | DC 150W, RF200~400W |

| Max processing speed | 900mm/s | |

| Resolution | 0.003mm | |

| CAM | Dedicated CAM program | |

| Drive system | AC Servo System | |

| Axis driving method | Ball Screw | |

| Operating system | Windows | |

| Input method | USB, Ethernet | WIFI |

| Assist gas | Air, Oxigen | |

| Fire detection safety device | Flame detection laser cut-off option | |

| Cuttable material | Wood, Atrile, Cloth, Paper, Mild steel, Stainless steel | |

| Power supply | AC 220V 50/60Hz 1P | Inquiry for export |

Equipment Features

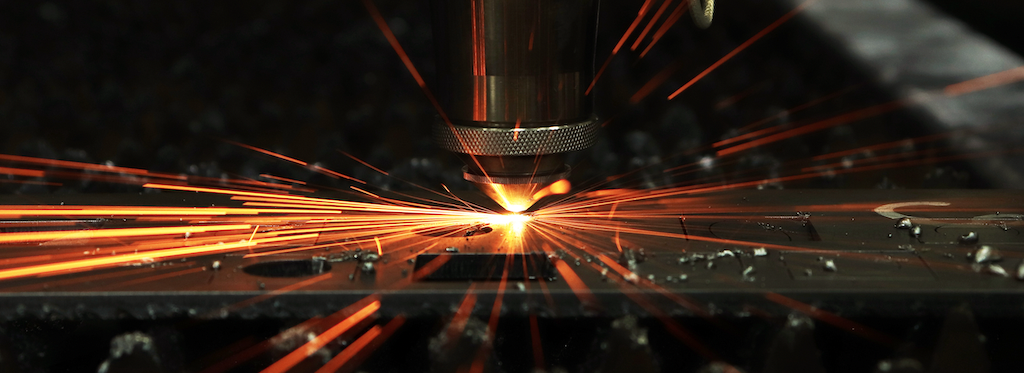

TALENTO9 hybrid is a 2021 all-new change model in which RMTECH's technology is concentrated. It is a metal-nonmetal combined equipment capable of cutting and marking non-metal materials as well as some metal processing such as carbon steel and stainless steel.

It has a wide processing area (1300x900mm) corresponding to the 4*8 width and maximizes precision and durability with a high-rigidity frame structure.:

RMTECH's patented beam integration technology is applied (option), and ACS (Anti Corrosion System) structure is adopted to protect the instrument from harmful gas operation.

For the safety of the user, it is designed to prevent the risk of fire by cutting off the laser power when a fire is detected during operation.

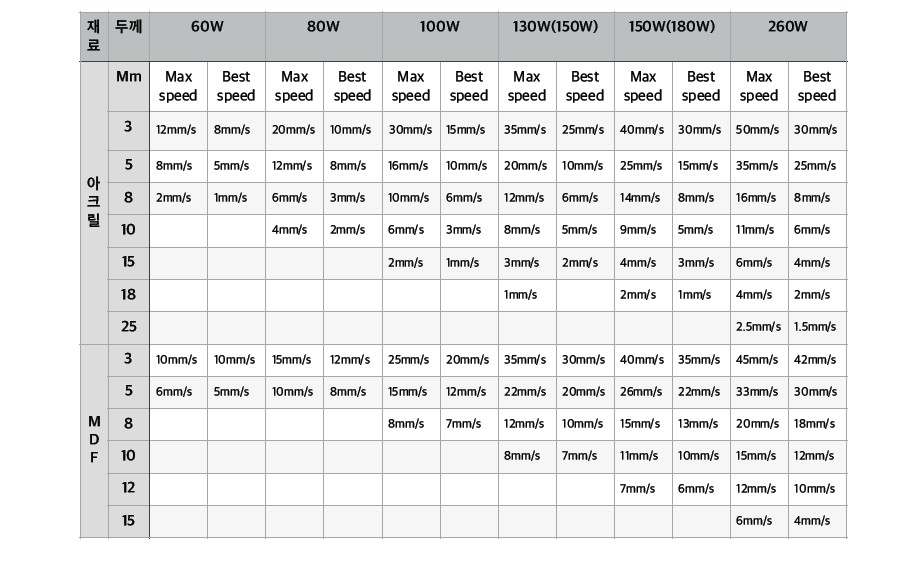

CO2 laser 150W~300W (DC TYPE), up to ~650W (RF TYPE) can be selected according to the purpose of the laser oscillator.

We make the most of our own design and production to the fullest and respond immediately to the functions requested by users.

Direct design! domestic production! The TALENTO series is designed and produced directly at the RM Tech factory in Yongin Techno Valley Industrial Complex, Gyeonggi-do.

It is a domestic product that is simply imported in the name of OEM production and is on a different level from Chinese products sold on the market in terms of quality and follow-up management.

-

Application of ACS System

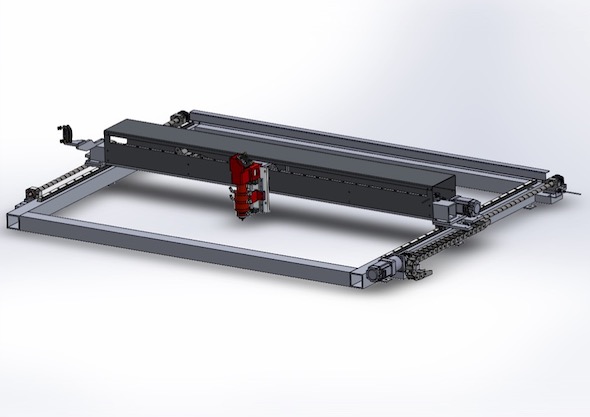

Vibration was minimized by applying a high-rigidity main frame, and distortion was prevented through a heat treatment process at 1100 degrees for 20 hours.

-

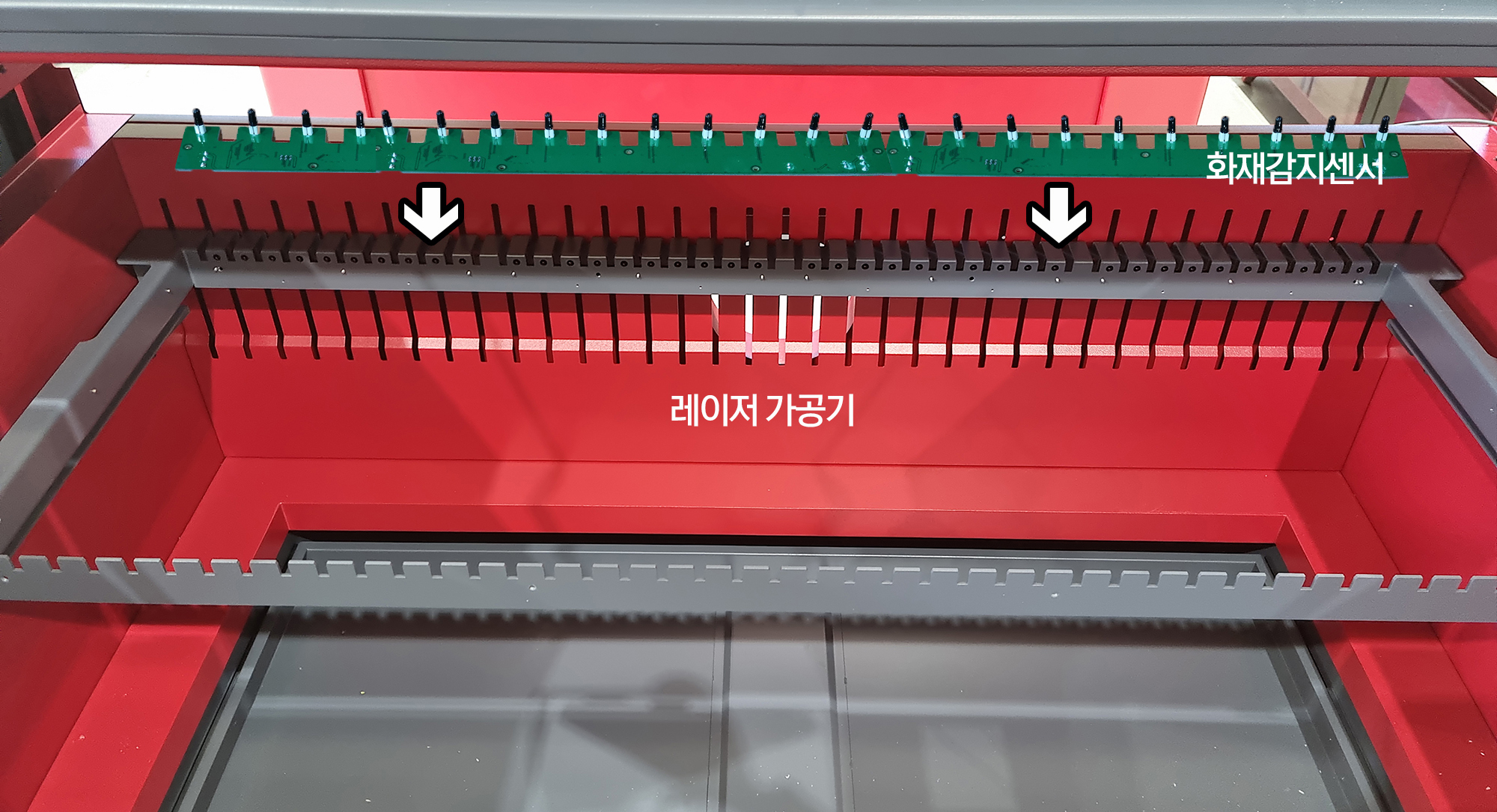

Fire detector

If a fire is detected during operation, the laser power is cut off to prevent the risk of fire. (Fire detection device patent) -

Safety cover applied

A safety cover is attached to the front of the processing area, so you can safely check the work progress.

When the safety door is opened, the operation can be set to be regular.

-

Dual wide display

For the user's convenience, the existing DSP panel has been upgraded to reduce inconvenience in operation and to make work easier by embedding a PC for operating the equipment.

-

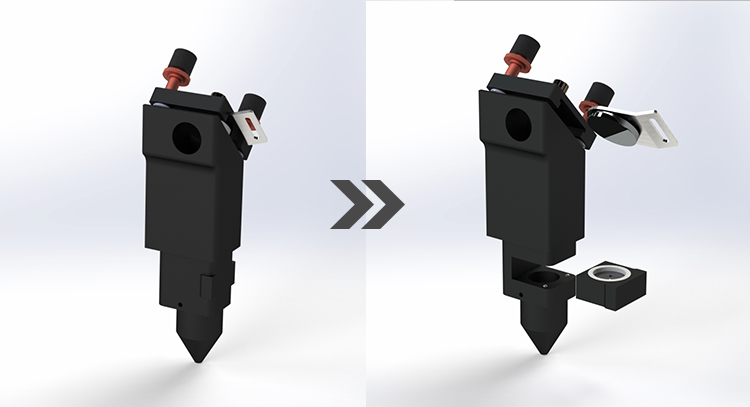

When replacing lenses and mirrors, the Open-Closed method was adopted to minimize cumbersome work and increase convenience.

-

By applying high-rigidity main frame and ball screw, vibration is minimized and high precision and durability are maximized.

Option

-

CCD dome automatic recognition cutting

After using a CCD camera and a dedicated program to print actual images, recognize the images to perform precise cutting.

available as an option

-

RF Co2 Laser selectable

Basic application of DC type glass tube CO2 laser,

RF type laser can be selected according to customer's request.

Material Processing Sample

-

acryl

-

paper (Korean paper)

-

leather and fabric

-

metal marking

-

wood

-

glass marking