CNC SYSTEMS

CNC Router

PRIMECUT48 ATC

| Basic Specifications | Options | |

|---|---|---|

| Work area | 1220 X 2440 X 180 | |

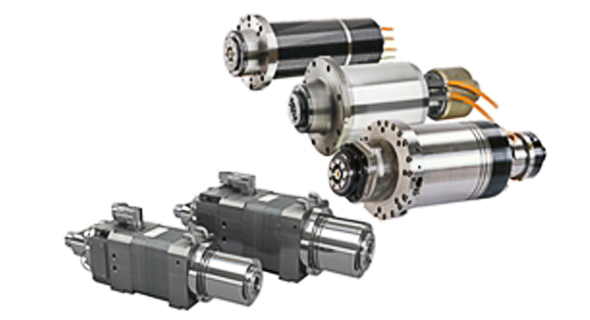

| Spindle motor | High frequency spindle 5.5Kw 24,000RPM BT30 | High frequency spindle 9Kw 24,000RPM BT40 |

| Drive | AC Servo motor | |

| Max moving speed | 12M/min | |

| Repetition precision | 0.05mm | |

| Feed precision | 0.03mm | |

| CAM | Dedicated CAM program | Aspire, V-CARVE, MASTERCAM, TYPE3, ARTCAM, SOLIDCAM, VisualCAM |

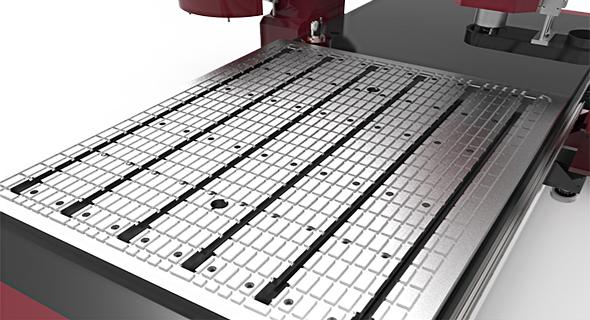

| Table | Vacuum table | T Slot, vacuum simultaneous use table |

| Controller | NK280 | FAGOR, CSCAM |

| ATC(Auto Tool Change) | Linear type 8pcs | Turret type 12pcs |

| Power supply | AC 380V 60Hz 3phase | Export: AC220V,240V, 400V selectable |

Additional Options

Cover production possible / Customization by size possible

Equipment Features

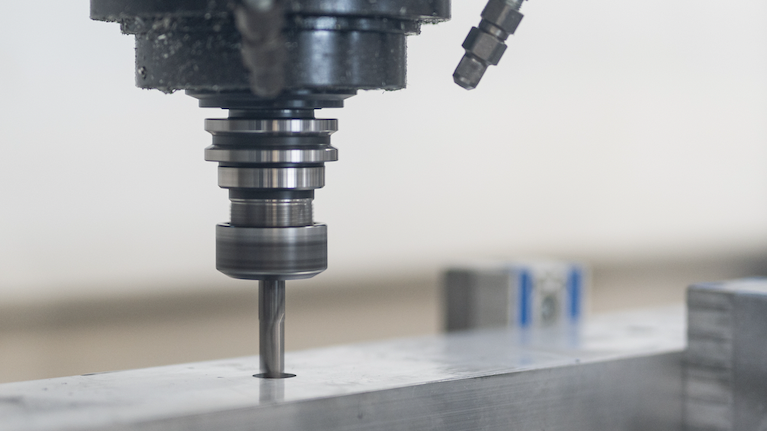

PRIMECUT48-ATC is a medium-sized CNC machine with a machining area of 1300x2500x180mm.

Sufficient processing area is guaranteed even in a narrow working environment.

Based on the frame heat treatment process and precision machining process through direct design, it has excellent precision and durability, and metal materials such as aluminum are also capable of precision/continuous machining.

Equipped with an automatic tool changer (ATC), it greatly helps to improve productivity.

Depending on the material to be processed, an appropriate spindle can be selected, and an efficient work space can be used by applying a gantry structure.

High-performance servo motors are adopted as standard and industrial controllers are adopted to maximize work stability and efficiency.

We can provide various types of processing JIG based on the processing DB for each material, and promise stable technical support until mass production through equipment installation and optimized training.

Direct design! domestic production! The PRIMECUT series is designed and produced directly at the RM Tech factory in Yongin Techno Valley Industrial Complex, Gyeonggi-do.

It is a domestic product that is simply imported in the name of OEM production and is on a different level from Chinese products sold on the market in terms of quality and follow-up management.

-

Excellent stability and durability by applying heat treatment bed and high-strength gantry structure

-

You can select a spindle that suits the characteristics of your work by torque, RPM, and output.

-

Precise machining is possible by using a high-quality precision motor

-

Basically, a vacuum bed is applied, and a T-SLOT combined vacuum bed can be selected as an option.

-

Productivity is maximized by applying industrial controllers, and various high-performance controllers can be applied according to customer needs.

-

For user convenience, an automatic tool changer can be selected, and various functions can be customized according to user needs.

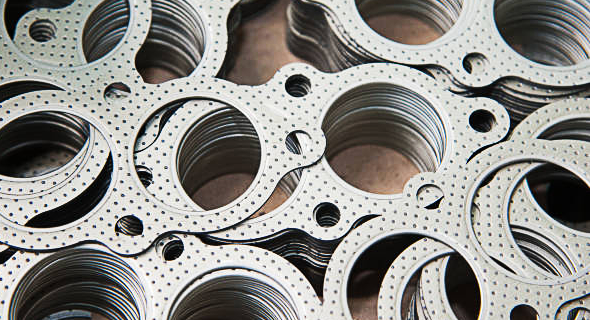

Material Processing Sample

-

stone

-

Acrylic • Plastic • Resin

-

aluminum • metal

-

Wood and other natural materials

-

composite panel

-

Furniture • Companion goods