LASER SYSTEMS

Laser applied FA equipment

VISION EDGE TRIMMING MACHINE

| Basic Specifications | Options | |

|---|---|---|

| Work area | 450 x 450mm (Can process 2 pairs of shoes) | 900*900mm |

| Laser | CO2 laser, (10600nm), 180W(Basic) | 120~400W(RF TYPE) |

| Processing material | Remnants of outer edges of shoe soles (rubber) up to 450 mm in size | |

| Processing purpose | Recognizes the outside to be cut as a vision and laser cuts the remainder of the outside | |

| Aixs driving method | Step motor + Timing Velt&Pulley | |

| MAX. processing speed | 600mm/s | |

| Repetition precision | ±0.01mm | |

| MACHINE VISION | High-resolution camera transcription method align | |

| CAM | Exclusive cam for CCD (including self-development) | |

| Cooling method | Water cooling | |

| Operating system | WIN10 | |

| Power supply | AC 220V 60Hz 1P |

Additional Options

Equipment operation computer / monitor selectable

Cover production possible / Customization by size possible

Equipment Features

In the shoe manufacturing process, it is specially designed equipment to improve the efficiency of the process by recognizing the outer residue of the outsole with vision and cutting it with a laser.

The process using the existing manual trimming machine has been dramatically improved, and it is designed to be linked to an automated line.

By applying a precision vision system and a vacuum table that transfers the workpiece vertically, speed, precision, and stability of processing are realized.

Maximized productivity by installing a self-developed program to operate with pre-stored data such as laser parameters, drive shafts, and product sizes.

Direct design! domestic production! VISION EDGE TRIMMING MACHINE is designed and produced directly at the RM Tech factory in Yongin Techno Valley Industrial Complex in Gyeonggi-do.

It is a Korean product that is different in quality and follow-up management from Chinese products that are simply imported and sold in the market under the name of OEM production.

-

Optimal workability is ensured by using a high-precision scanner

-

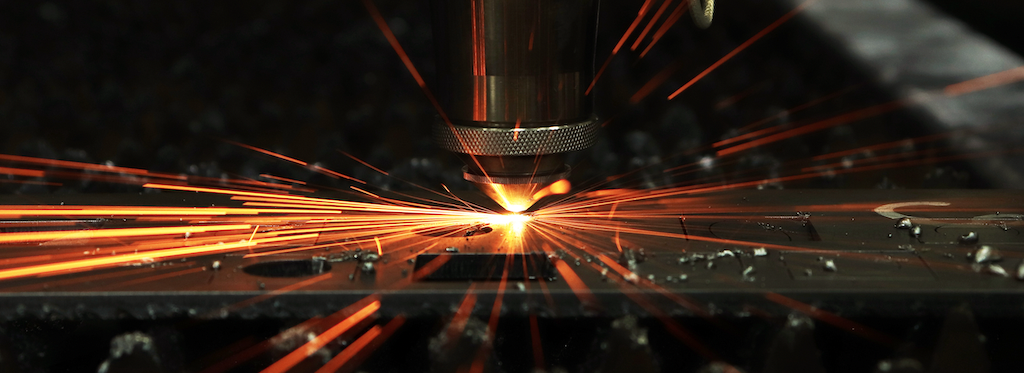

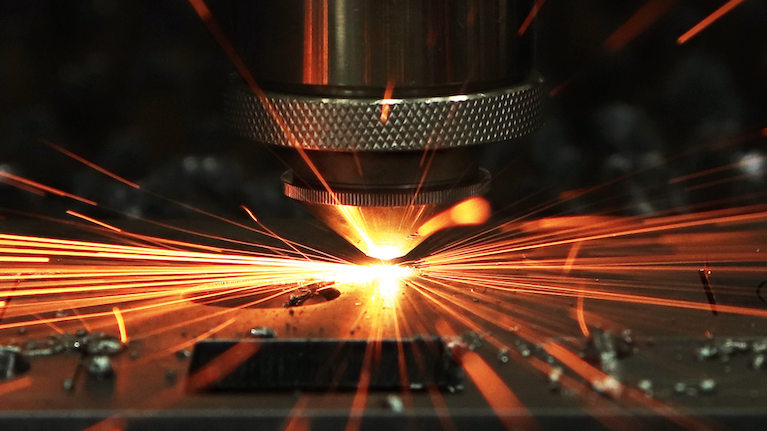

Equipped with co2 laser suitable for work purpose

-

Applicable design for automation line

-

Equipped with VISION cameras to ensure maximum efficiency and productivity

-

Provides program development solutions according to user requests

-

Application of vacuum table

It is designed to be processed by providing irregularities in the shape of a shoe and to maintain a vacuum during processing by configuring a dense vacuum generating section.

Material Processing Sample

-

Existing manual equipment

-

Various materials and sizes available

-

molding

-

trimming sample