LASER SYSTEMS

Laser marking machine

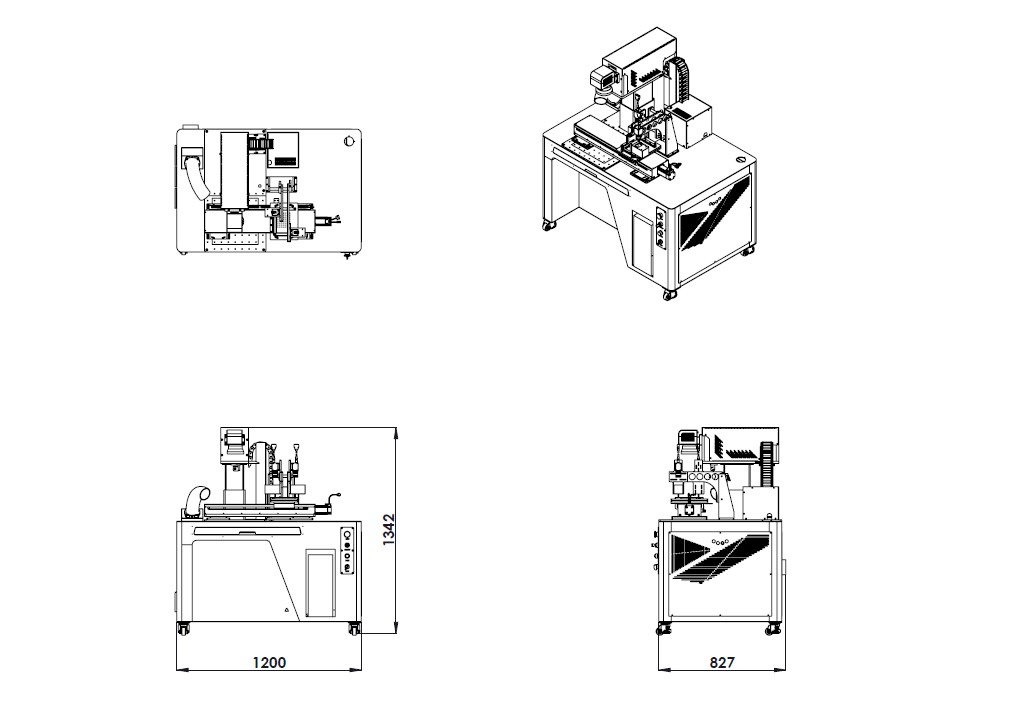

MARKA UV

| Basic Specifications | Options | |

|---|---|---|

| Work area | 100*100mm | 300*300mm |

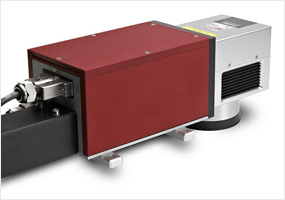

| Laser | UV laser, 355nm, 5W(Basic) | 2~40W |

| Axis driving method | Scanner type | |

| Max. marking speed | 2500mm/s | |

| Repetition precision | 0.002mm | |

| CAM | Marking mate/EZCAD | SAMLight |

| Cooling type | Water cooling | Air coolng |

| Operating system | WIN10 | |

| Power supply | AC 220V 60Hz 1P |

Additional Options

Possible to add CCD function / Possible inline design

Equipment operation computer / monitor selectable

Cover production possible / Customization by size possible

Equipment Features

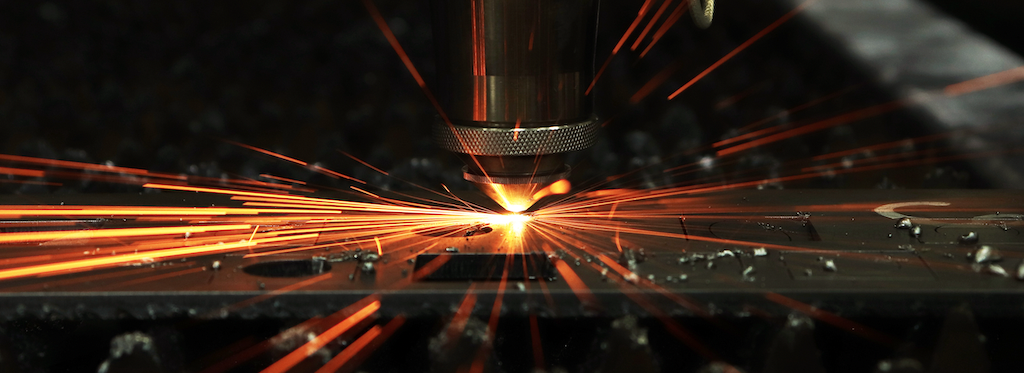

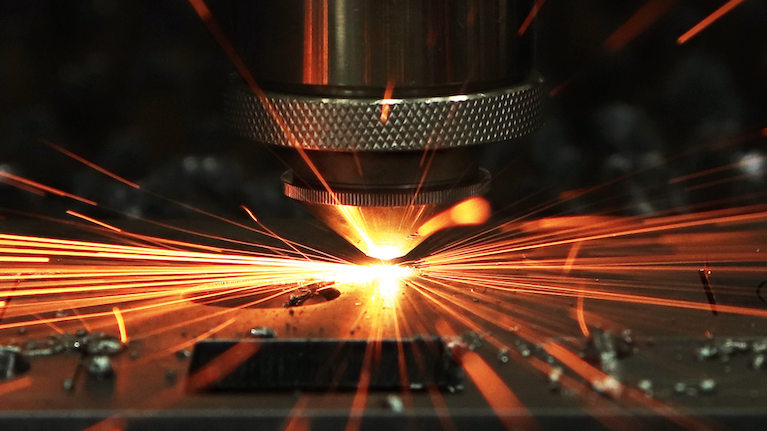

Since laser marking uses the characteristics of a laser beam with high-density energy to process the surface, it can sufficiently compensate for the disadvantages of conventional marking methods such as printing or engraving.

Therefore, in various industries such as semiconductors, mobile phones, automobiles, plastic processing and metal industries, it is not only applied to marking product serial numbers, company names, and expiration dates, but also cuts, drills, welds, and heat treatment according to output. It is widely applied to various high-tech industries.

In particular, this product has a very high absorption rate for each material with a short wavelength corresponding to 1/3 of the wavelength of the fiber laser, so it can be processed without thermal stress for applications that require marking with reduced visibility and product damage.

RMTECH's laser marking machine is evolving while perfectly responding to the needs of users in addition to the existing models.

We can provide various types of processing JIG based on the processing DB for each material, and promise stable technical support until mass production through optimized training after equipment installation.

Direct design! domestic production! The MARKA series is designed and produced directly at the RM Tech factory in Yongin Techno Valley Industrial Complex, Gyeonggi-do.

It is a domestic product that is different in quality and follow-up management from Chinese products that are simply imported and sold in the market in the name of OEM production.

-

The use of a high-precision scanner guarantees optimal workability.

-

You can choose the right laser for your output and workpiece

-

Processing jigs suitable for the characteristics of various materials can be installed.

-

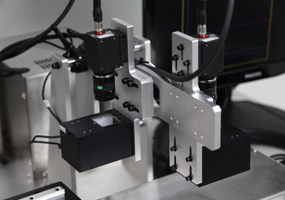

VISION Cameras and other devices are added to ensure maximum efficiency and productivity.

-

Provides user convenience by applying the optimal program and can apply various programs according to customer needs.

-

The combination of laser and scanner enables design to be applied to various automation lines.

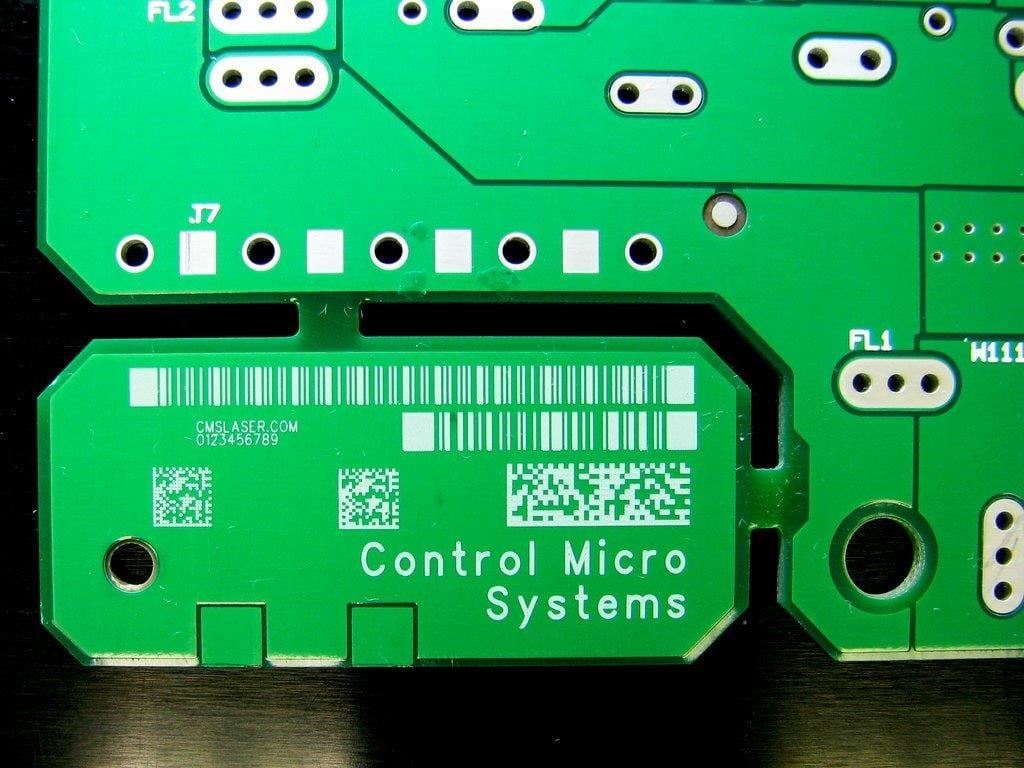

Material Processing Sample

-

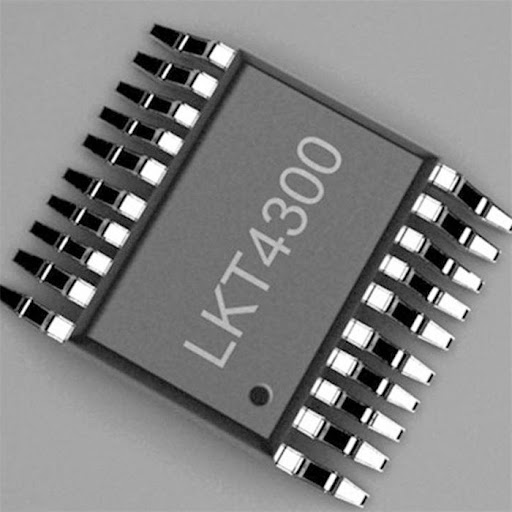

PCB

-

Various plastics and resins

-

semiconductor

-

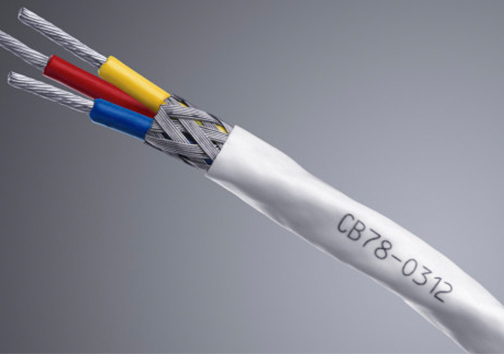

CABLE

-

glass

-

etc