LASER SYSTEMS

Fiber laser cutting machine

VULCAN 9060

| Basic Specifications | Options | |

|---|---|---|

| Work area | 900*600mm | |

| Laser | nLIGHT(USA) 500W~6KW | RAYCUS / MAX / JPT |

| Laserhead | Raytools(SWISS) | PRECITEC / Ⅱ-Ⅵ |

| Controller | Dedicated controller | FUNAC / Cypcut / Hypcut |

| CAM | Steel plate processing program | LANTEK / SIGMATEK |

| System | High inertia servo motor system | |

| Axis driving method | Rack&pinion | Ball Screw / Linear drive |

| Max ACC. | 2.5G | |

| Max. cutting speed | 100000mm/min | |

| Position precision | ±0.1mm/3,000mm | ±0.01mm |

| Repetition precision | ±0.03mm | ±0.003mm |

| Power supply | AC380V, 220V 60Hz |

Equipment Features

The VLUCAN 9060 is a machine designed to reasonably respond to the needs of manufacturing small/precision metal workpieces.

Non-ferrous special metals such as copper, brass, bronze, tungsten, silver and gold can also be processed.

In particular, it efficiently supports rapid sample production and product production in universities, laboratories, corporate research centers, and precious metal processing companies.

Linear drive system can be adopted as an option, and various elements necessary for user safety such as safety full cover and special coated glass are included.

Various function options such as automatic clamping and automatic roll material feeder are available.

-

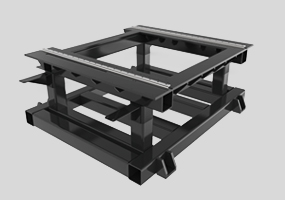

Application of high rigidity frame

Vibration was minimized by applying a high-rigidity main frame, and distortion was prevented through a heat treatment process at 1100 degrees for 20 hours.

-

Safe full cover application

It has a shielding cover to block the laser beam reflected from the processing material, so it can be used safely.

In particular, there is no problem at all for indoor use such as offices or research laboratories.

-

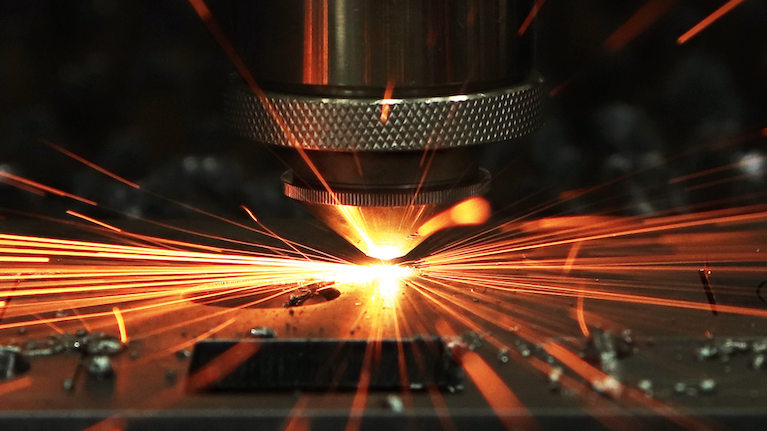

Highly reflective metal processing possible

The patented Fiber Laser technology fundamentally blocks the reflected light reflected from metal so that the laser generating device is not damaged, and materials that cannot be processed with conventional lasers, such as copper, aluminum, gold, silver, and brass, can be processed without damaging the equipment. do.

-

Applicable to various laser oscillators

Various laser oscillators can be applied with the desired configuration depending on the purpose of work, material characteristics, laser output, and manufacturer.

Option

-

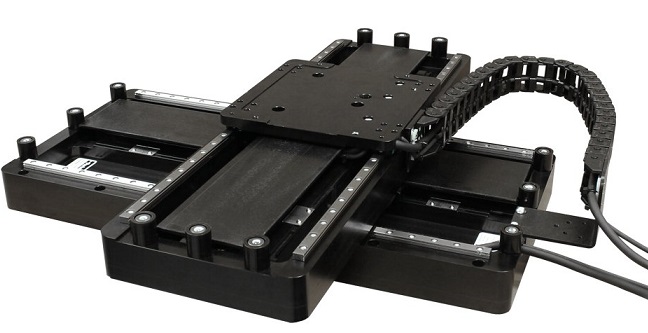

Linear Motor System selectable

Basically, Servo+Rack&Pinion System is applied.

Linear Motor System can be selected and applied as an option.

When applying the linear system, there is no wear on the driving part and more precise machining is possible.

-

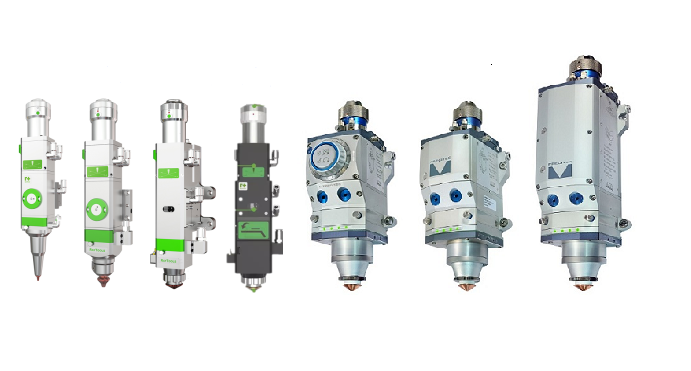

Head for fiber can be selected

The laser head must be applied according to the purpose of work, the characteristics of the material, and the laser power.

Dedicated laser head is an important part, so it will be decided through consultation.

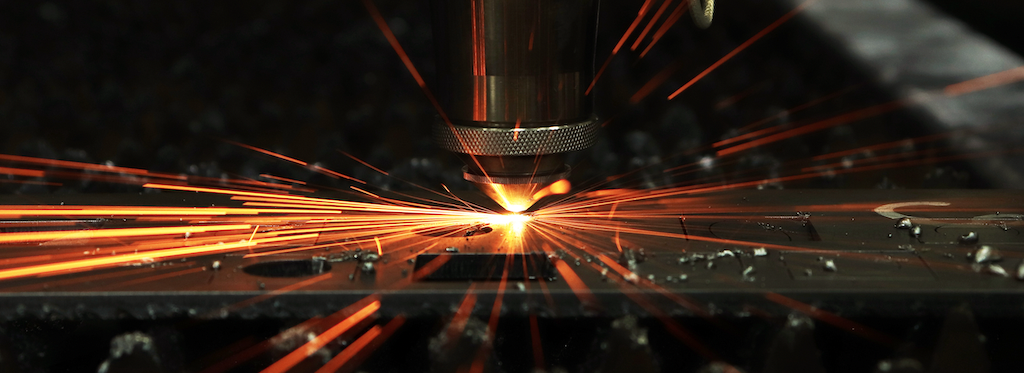

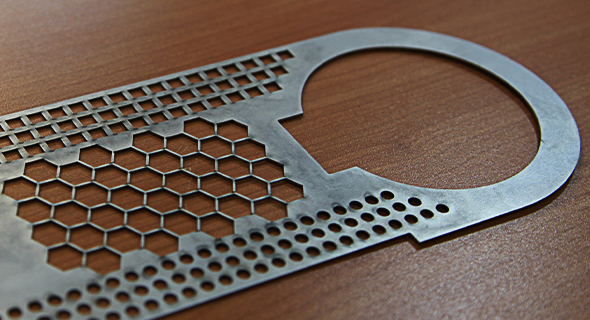

Material Processing Sample

-

metal

-

non-ferrous metal

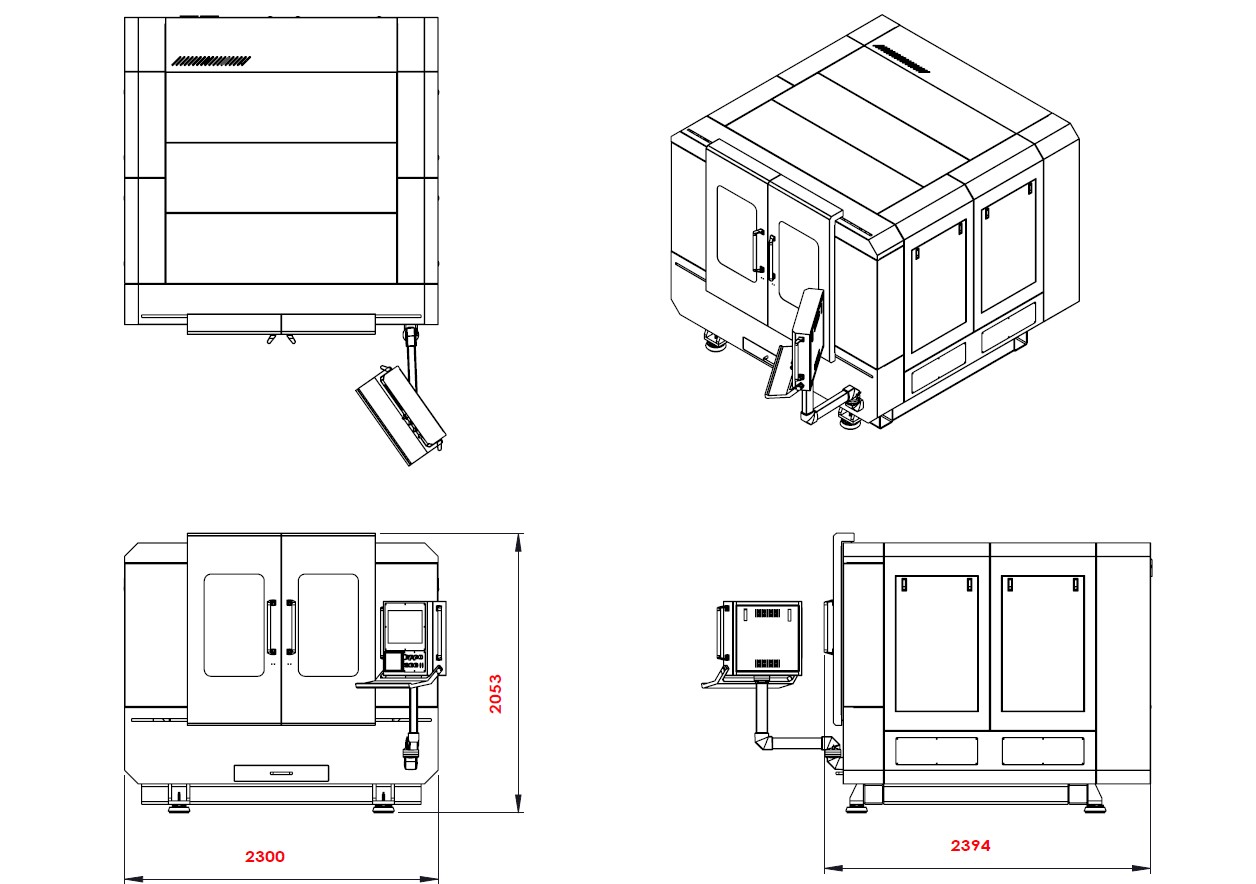

Outline drawing and size

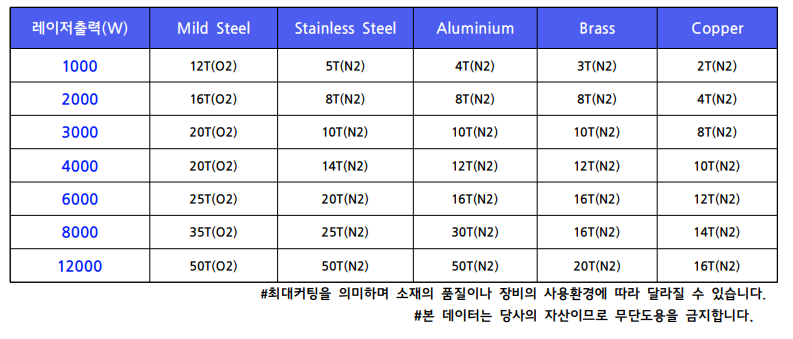

Cutting Capacity

-

#Indicates maximum cutting and may vary depending on the quality of the material or the usage environment of the equipment

#This data is our property, so unauthorized use is prohibited.